+65 years of experience

20k multinational projects

Design and manufacture of expansion joints

Our extensive experience and flexibility allow us to develop successful solutions that meet the needs of our clients.

Our Products

Custom-made expansion joints

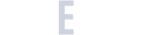

Rubber Expansion joints

Expansion joints, or rubber compensators, are flexible connections made from elastomers, reinforced with technical fabric and metal rings. Expansion joints relieve stress in piping systems caused by temperature changes, vibrations, and movements.

- 1 to 4 Convolutions.

- DN25 to DN3600.

- Temperature up to 150ºC.

Metal Expansion joints

Metal expansion joints are used wherever high temperatures, aggressive fluids, or high pressures are present. They can be designed and produced for a wide range of applications.

- Single or double bellows.

- Dimensions up to DN6000.

- Temperature depending on the alloy.

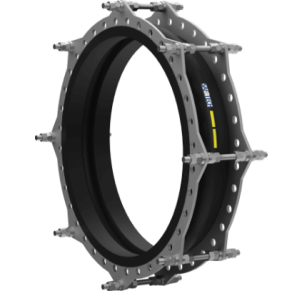

Fabric Expansion joints

Fabric expansion joints are single or multilayer construction made from glass, silica and ceramic fibers, steels, fluoroplastics, insulation materials and elastomers. The Fabric expansion joints absorb vibration and movements caused by thermal changes, relieving stresses in ducting systems.

- Single or multi-layer.

- Unlimited dimensions.

- Temperature up to 1,000ºC

We will help you choose the expansion joint that best suits your needs

Our case studies

About us

Specialists in custom manufacturing

We are a company specialized in the manufacturing of expansion joints tailored to the needs of our clients.

Frecuently asked questions

What type of expansion joint does Safetech offer?

Safetech manufactures rubber, metal and textile expansion joints, suitable for various industrial applications. Essentially within the water, power generation, petrochemical and mining sectors.

How to choose the right expansion joint for your project?

The choice depends on factors including temperature, pressure, fluid type and system movements. Our technical team will advise you to guarantee the safest and most efficient solution.

Does Safetech offer personalised solutions?

Yes, we design and manufacture custom expansion joints to the specific requirements of each customer and project.

What materials does Safetech use in its expansion joints?

We use high quality materials such as stainless steel, special rubbers and technical fabrics, selected depending on the requirements of the operating environment.

Do Safetech expansion joints comply with international regulations?

Yes, our joints are designed and manufactured according to international standards such as ASTM-F1123, PED, EJMA and EN14917.

What is the usual delivery time for expansion joints?

Timelines vary depending on the type, scope and complexity of the project. We always strive to offer competitive delivery times that meet our customers’ needs.

What maintenance do Safetech expansion joints require?

We recommended periodical visual and functional inspections. Proper installation and use within the specifications will prolong its useful life. If you require more information, please ask us for our maintenance guide.

Where can I get more information or request a quote?

You can contact us via our website, where you will also find catalogues and detailed specification sheets.